Building a platform to enable manufacturers to make more with less at Oden Technologies

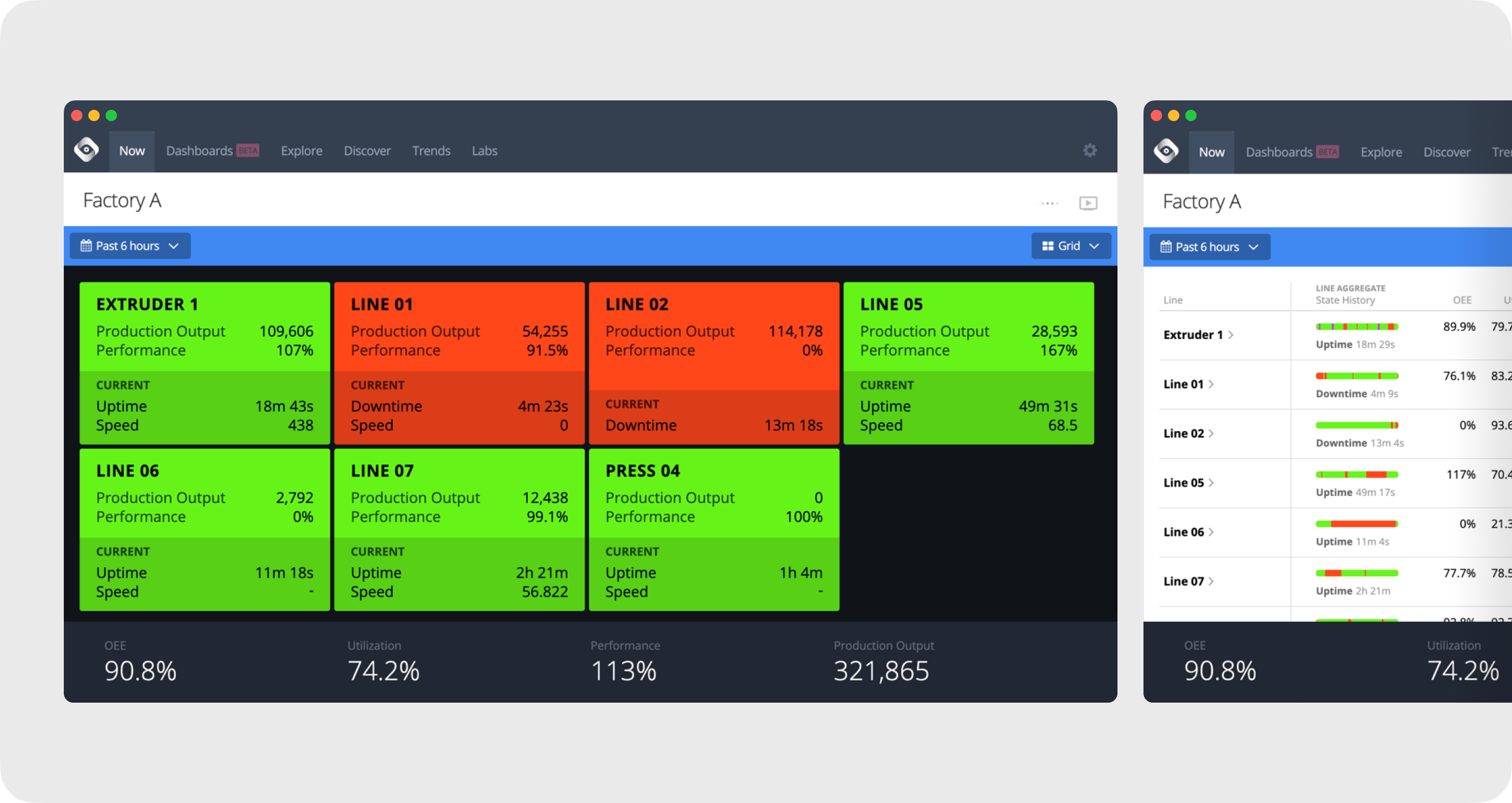

I designed a product for manufacturers to monitor and manage their factories in realtime, resulting in $8,000,000 in annual productivity increases per factory.

Customer goal Get more sellable product from the equipment and staff we have today.

Business goal Create an offering where customers actualize value from their data within 30 days.

My Role Product Design lead.

Challenge

How to get factories get value from their data

Oden Technologies was able to provide limitless manufacturing process data to its manufacturer customers … but these customers weren’t using the data they said was so important to them. Why?

My task was to figure out where the gap was, if it was addressable, and if so, how Oden could close it. How could I increase the profit margin of an operation by $10,000,000?

Discovery & Exploration

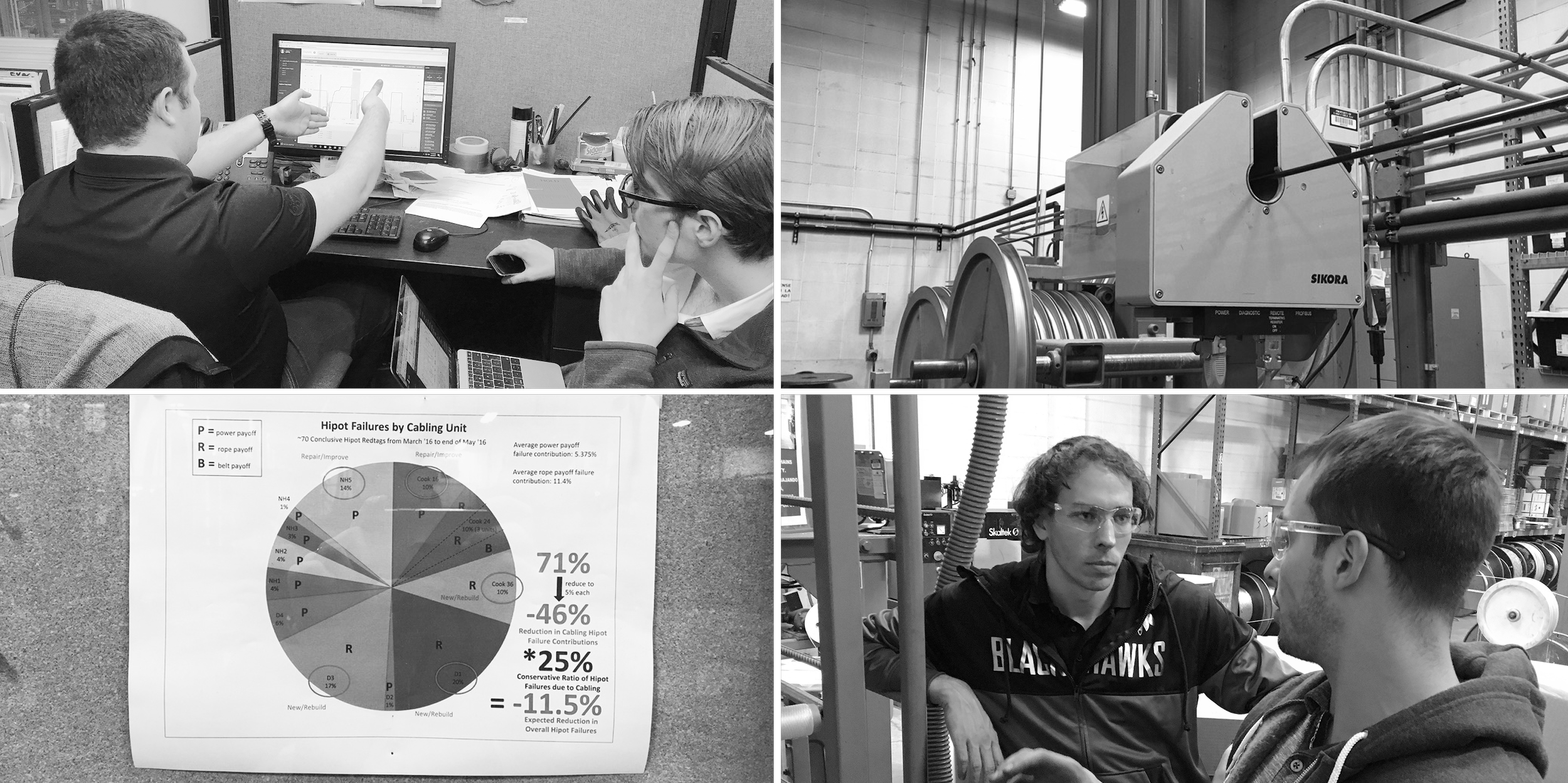

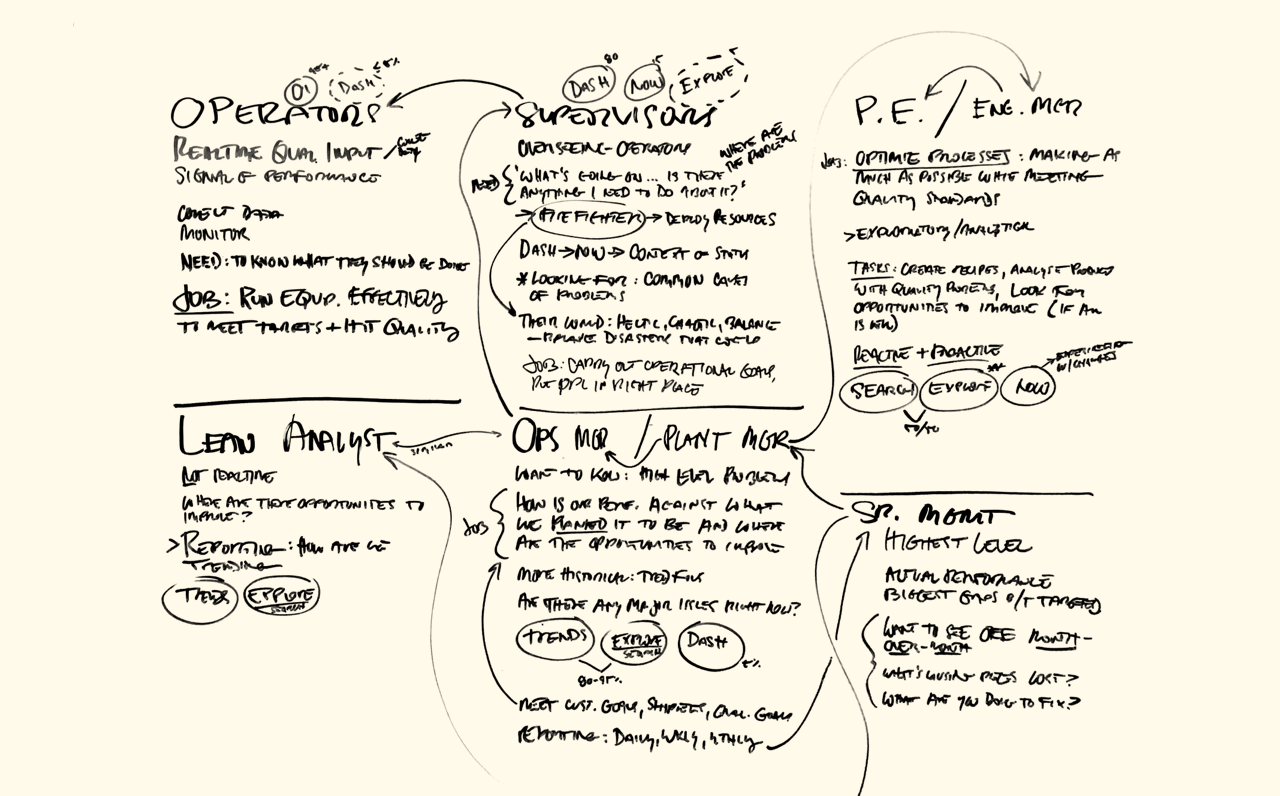

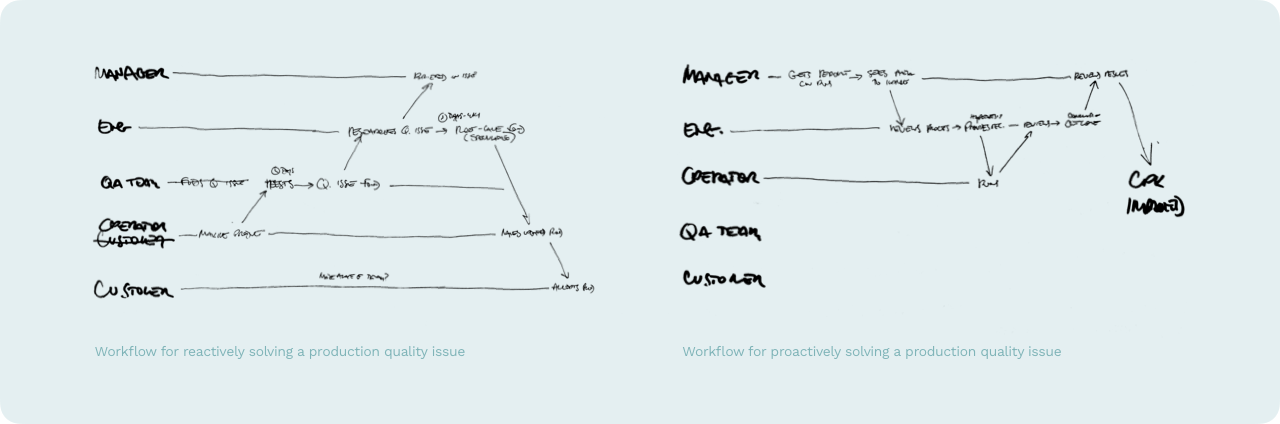

I hit the ground, visiting factories and observing the different roles, tools, and processes. I benchmarked other tools, interviewed experts, and talked with our sales team. From this, I built a map of the problem space, based in roles, responsibilities, and outcomes, that allowed me to identify the most significant blockers and opportunities through discussion with the internal team.

Exploration & Ideation

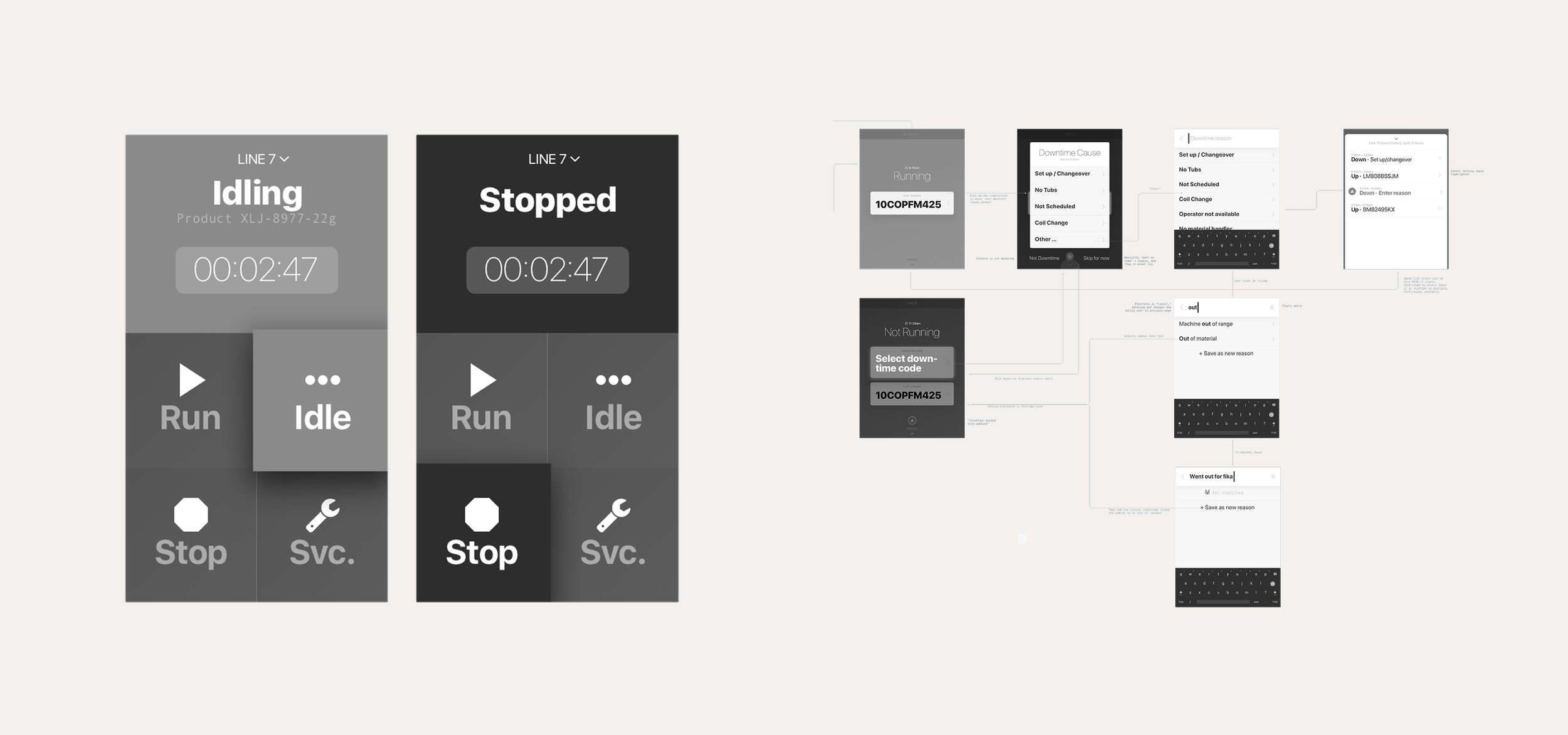

I explored solutions for different target users and form factors, to validate who our product was for and the most appropriate medium for interacting with the system. Web app, mobile app, tablet app. I explored different scales of automation, prediction, and manual user input.

Pivots

Through prototyping, I learned one of our primary target users was a dead-end: while they benefitted from the output, they weren’t a reliable source of data input. We pivoted away from them to a different, and controversial, target user. Their usage and the value they provided aligned with my research, and I did further deep research into their workflow to understand how to organically integrate in to it.

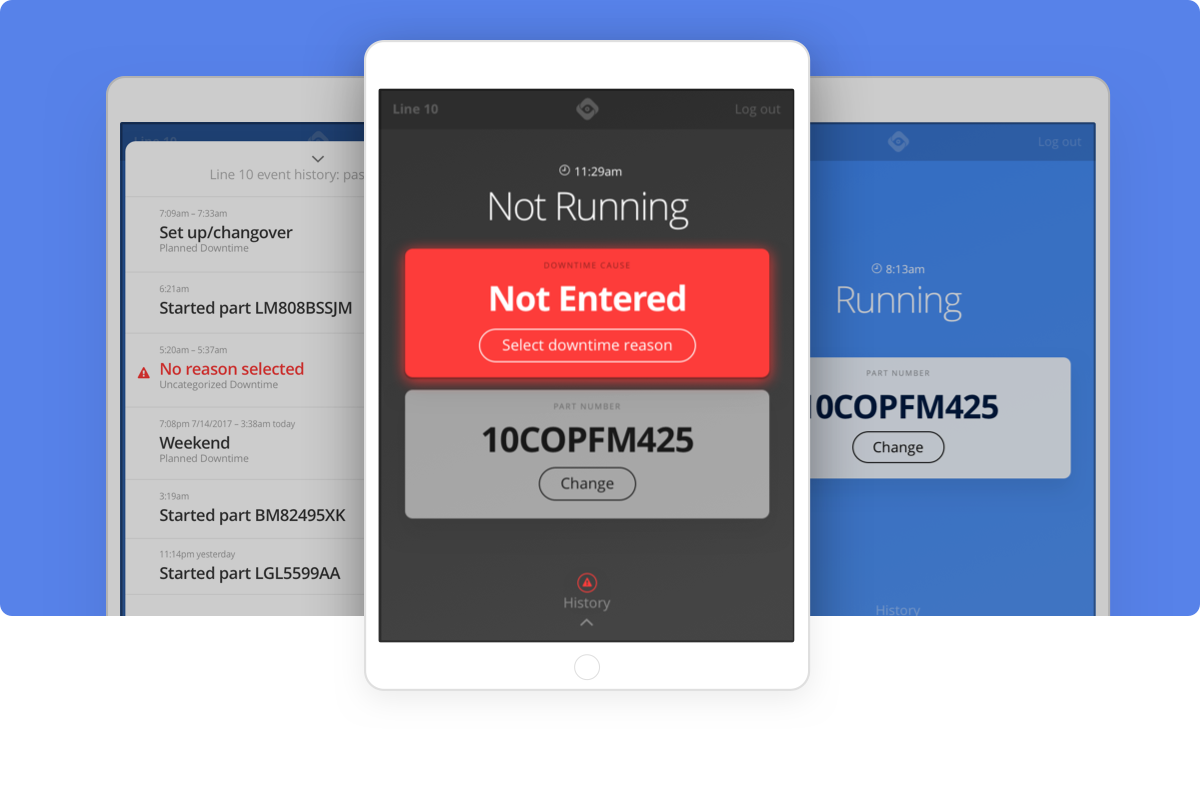

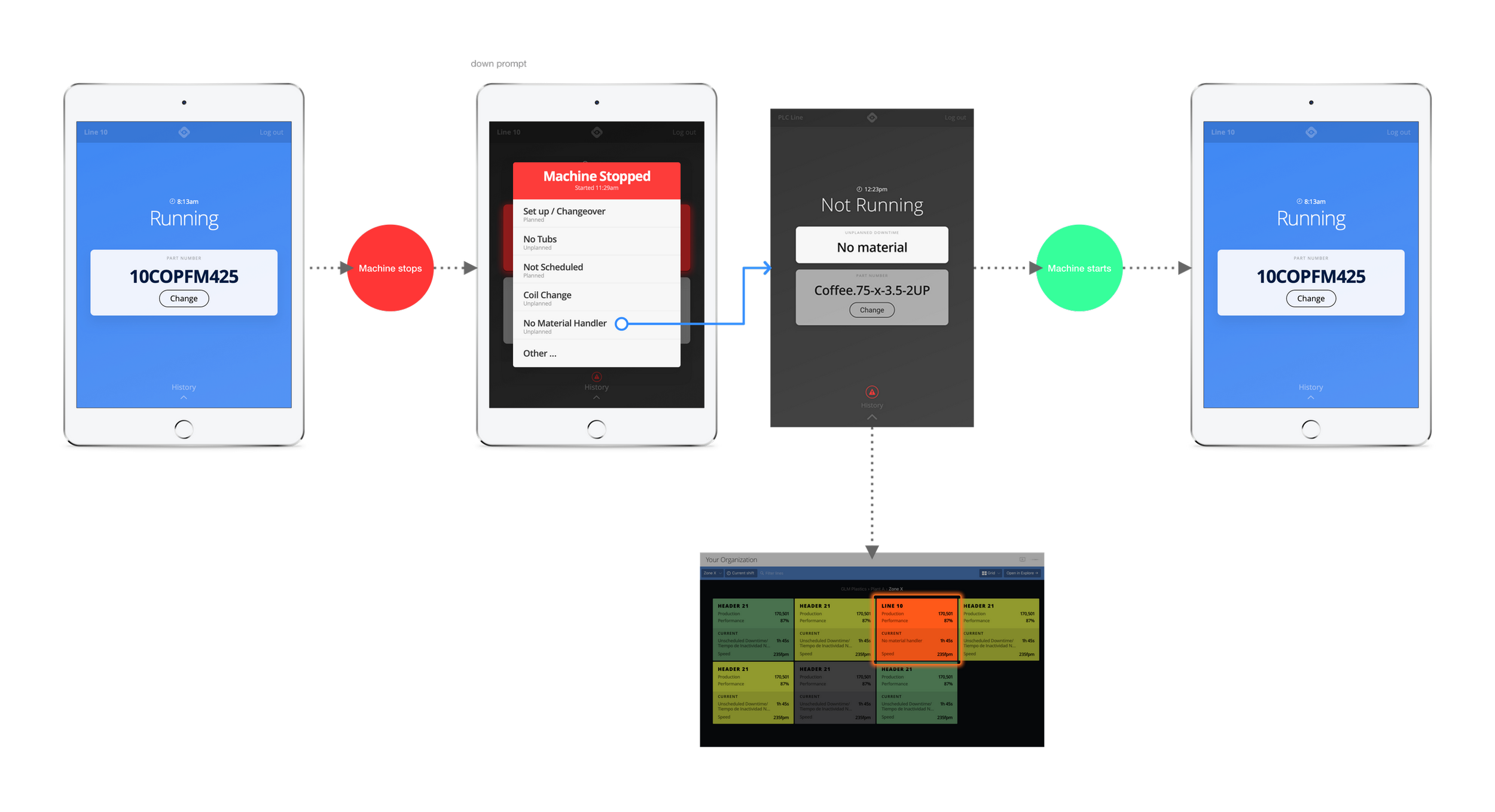

Solution

A product that meshes together data and human input, utilizing a dedicated tablet at the machine to display realtime process data and recommendations, and allow for operator input to classify events, ultimately feeding into Oden’s AI platform and going on to provide realtime automated classification, event detection, and process recommendations.

Result

Following deployment and operationalization of these new tools, manufacturers have seen capacity increases of 8% (on $100,000,000 annual revenue) and improvements in quality that amount to a 25% reduction in cost.